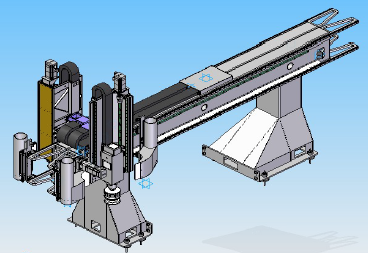

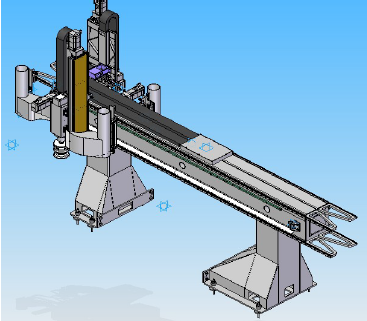

Finite element analysis and optimization of the structure of a machine tool

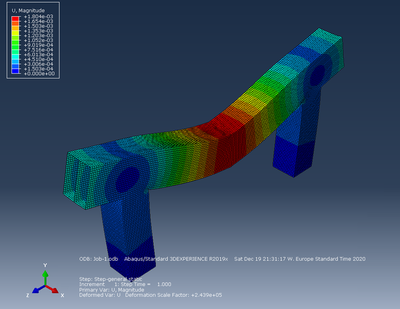

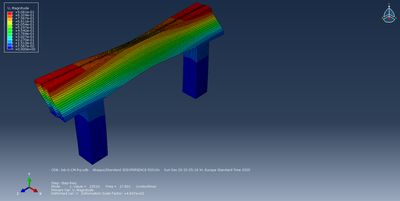

Displacement in the First mode (25.496 cycle/time) with the new cross section. T=3 mm

Displacement in the First mode (25.496 cycle/time) with the new cross section. T=3 mm

Finite element analysis and optimization of the structure of a machine tool

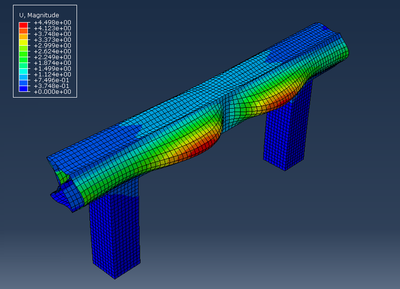

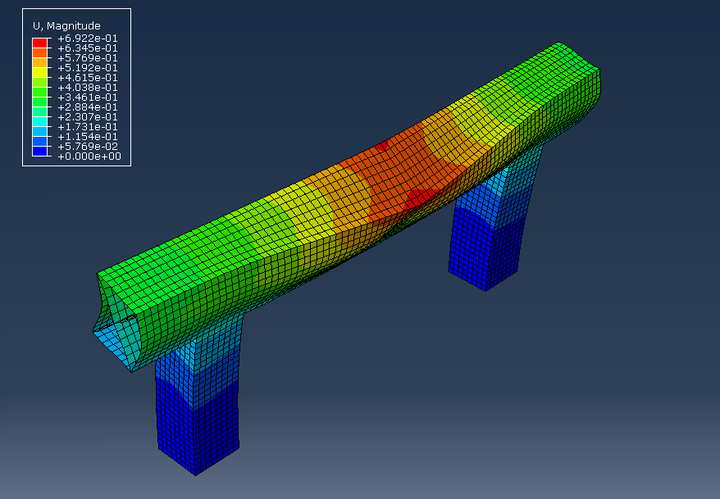

In this project, I analyzed the structural behavior of a machine tool system using the finite element method. I used Abaqus CAE to solve the FE problem in a 3D simplified model of the machine tool structure.

Then, I defined a sizing optimization for the cross-section of the structure to optimize the thickness and increase the first eigenfrequency by 25%. Lastly, I modified the geometry of the cross-section. The optimization process has been done on the modified cross-section to find the minimum thickness by minimizing the volume and satisfying the minimum requirements of the problem.